Your Warehouse is Too Small.

Why You Should Plan for Your Warehouse Capacity.

Either situation can get you into financial and operational trouble.

Too much warehouse space and you're burning cash on rent but not turning over inventory to pay for it.

Too little warehouse space and you can’t meet the demand you’ve spent so much time and money driving with your marketing efforts. Also, when you outgrow your warehouse you are often riddled with inefficiencies that drive down profit.

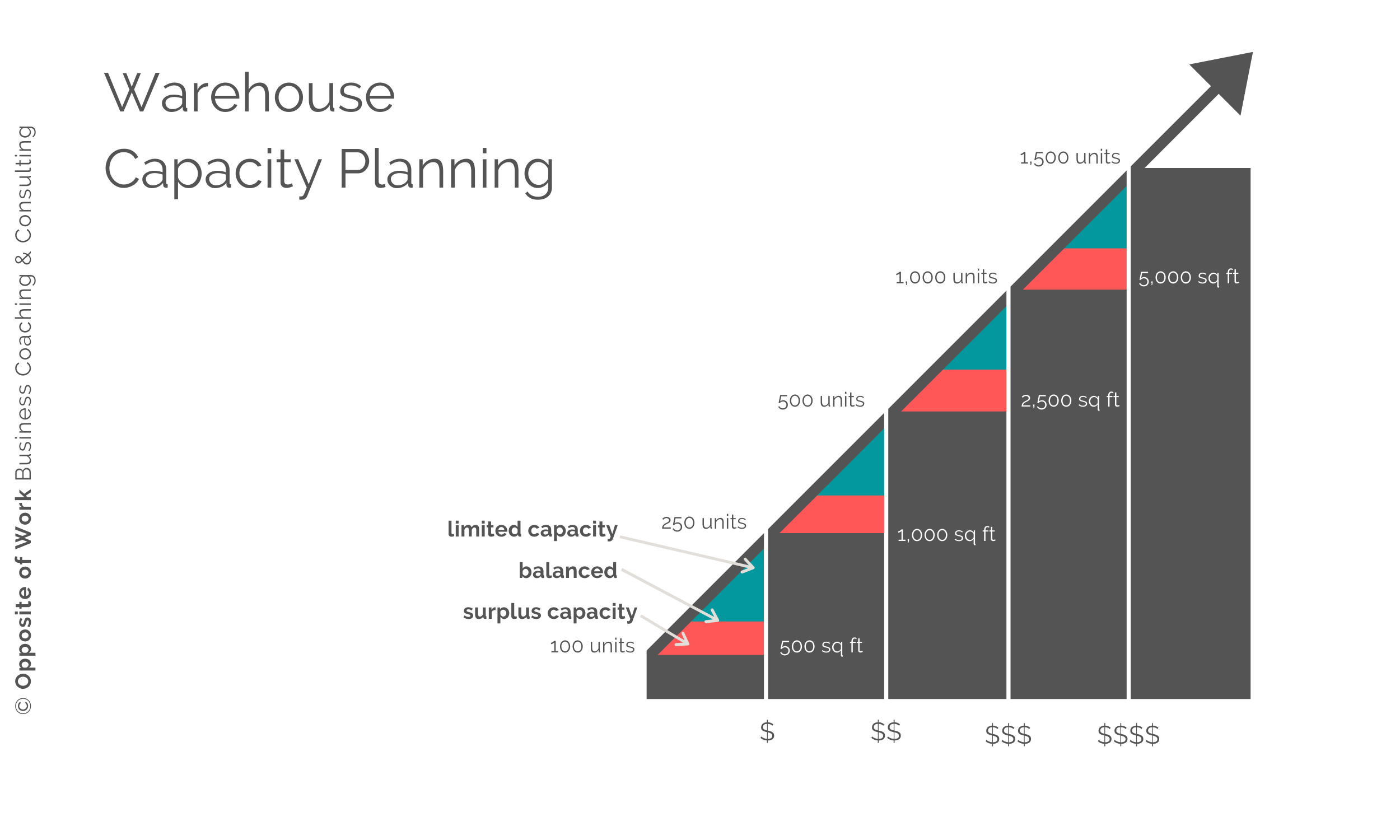

The chart below shows the progression of capacity and cost. When your warehouse capacity is balanced, you essentially have the right amount of inventory to sell to cover the cost of your warehouse space. The area in the green is ideal because you don’t have to spend more on your warehouse space, but have capacity for more inventory. However, as you get closer to the next level, your capacity becomes limited.

My Warehouse Capacity Story.

When running and operating my own inventory based eCommerce company, I experienced having both too much and too little inventory space.

Too much space often occurred right after moving into a new facility. Moves are costly and leases often require longer terms. You don't want to outgrow a new warehouse shortly after you moved and be stuck in a lease. So, you take on a larger location with the hopes that sales support the additional warehouse space.

As my company grew, we also had to deal with having too little space. This happened when we were outgrowing some of our first facilities. I had periods where we had to move pallets out in the parking lot in the morning in order to open up enough space to work in the warehouse. At the end of the day, we moved the pallets back into the warehouse. Inefficient at best and if it was dark or raining… even worse.

What’s the Answer to Warehouse Capacity Planning?

How do you handle this challenge of having too little or too much warehouse space at any given time? How do you ensure that you will know well in advance when your warehouse will be too small before it’s too late? How do you know how much more space you need when the time comes to move to a large facility?

The answers lie in cubic dimensions.

Cubic Dimensions

There are two things that matter here:

The total physical size of your inventory

The total physical storage capacity in your warehouse

Your cubic dimensions calculations matter today and in the future.

Today it matters because:

You need to know where you stand with regard to filling up your warehouse. Are you 25% there? Are you 50% there?

Knowing will also help you see opportunities for better data-driven decisions, such as keeping fewer large items in stock or ordering fewer units more often from certain suppliers.

In the Future it matters because:

You need to know when you will outgrow your current space. This is driven by both more inventory and limited space.

How much space you’ll need at the new location and how many years this space will be sufficient.

You need to measure your inventory and storage capacity. Once you do, you’ll have a whole new perspective on how to optimize your warehouse.

Let’s breakdown Inventory Cubic Feet and Storage Cubic Feet.

Inventory Cubic Feet

Use MEC, which stands for measure, enter, calculate.

Measure - each unit of inventory

Enter - the values into your inventory management system or a spreadsheet

Calculate - run the calculations to make decisions from

To get started, you need to measure each unique SKU of inventory you keep in stock.

Step 1 - literally measure a unit of each

Step 2 - enter the 3 elements into a spreadsheet or if you have a system that accommodates these fields then do it there

Step 3 - use a spreadsheet to calculate the cubic feet of each SKU using this formula:

L x W x H in inches / 1728Step 4 - Multiply the SKU cubic feet x the number of units you have in stock to arrive at your total inventory dimension

Watch my FREE mini course Warehouse Capacity Planning - Inventory Businesses [Free Google Sheet] for a demonstration on how to use MEC. Includes a free tool for your warehouse capacity planning.

Storage Cubic Feet

"In the same way you measured your inventory, you’ll need to measure your shelving and any other storage options. (See note above regarding my FREE mini course Warehouse Capacity Planning - Inventory Businesses [Free Google Sheet])

Use MEC again:

Measure

Enter

Calculate

Enter the data into a spreadsheet.

Measure all shelving.

W x D x H in inches / 1728

Measure each type of shelf you have and the quantity of each type.

Measure all bench tops and open floor space.

Using a reasonable amount of height, stack inventory on tabletops or on the floor. Calculate these areas.

For example, to utilize open storage space you used pallets with inventory stacked 4’ high. This would amount to 48 x 48" x 48" / 1728 per each pallet location.

Steps for determining storage cubic dimensions:

Name each unique storage type and enter into a spreadsheet. For example,

6-foot shelf, gray

8-foot shelf

Pallet space - zone 1

Pallet space - zone 2

Tabletop - zone 1Measure the dimensions of the storage types and enter into a spreadsheet

Sum all to find your current total storage capacity

Storage Space Variances.

There are a few factors to consider when calculating the total storage capacity.

Voids

You’ll never fully optimize your shelves because inventory comes in all different shapes and sizes. There will always be some void on the shelves

Unusable space

The shelves themselves consume some of the cubic dimensions.

Top shelf

The top shelf won’t be accounted for in the W x D x H dimension, yet may be able to consume an additional chunk of inventory. (See video for a detailed explanation.)

Accounting for variances

This has the potential for analysis paralysis.

I suggest using a global discount percentage to reduce the gross amount of storage capacity.

You could spot check a few shelves to literally compare what the model has versus how much is actually there and use that rate globally.

Warehouse Capacity Planning - Pulling it All Together.

Current State

After using MEC to determine inventory and storage cubic dimensions, you know the size of your inventory and the size of the available storage space.

inventory dimension / storage capacity = % used

Forecasting Warehouse Expansion

Now you can run forecasts surrounding expanding or modifying your inventory. Based on inventory changes, you’ll know how much additional storage capacity you’ll need.

Forecast Inventory Expansion

For existing SKUs - It’s just a matter of plugging in higher quantities for your existing inventory.

New SKUs - add new SKUs to the sheet with their dimensions and a forecasted amount that you’ll keep in stock.

Granular - you have the dimensions for the new product

General - you can plug in general numbers and just look at doubling your inventory size

This inventory tool is a way to see how your inventory expands based on various scenarios.

Forecasting Storage Expansion

Walk the warehouse and determine where you can fit more shelving and what type of shelving would work in each location.

You can always store more on shelves than the floor, so always assume that ultimately you’ll have mostly shelving.

Enter the details into a sheet and get your total capacity.

Benefits of Using the MEC Method for Warehouse Capacity Planning.

You know where you stand in supporting your business' growth.

You give yourself a longer runway for making huge decisions, like renting a larger facility.

You learn a lot about your inventory and can make tactical decisions to optimize it.

You may sleep better at night because you KNOW where you stand and what your timeframe is for having to move to a new facility.

In summary, the MEC process is:

Measure your current inventory and storage spaces.

Enter the measurements into your inventory management system and/or a spreadsheet.

Calculate and run scenarios for scaling inventory and storage capacity up or down.